Boiler System Support: Exploring Options for Installation and Repair

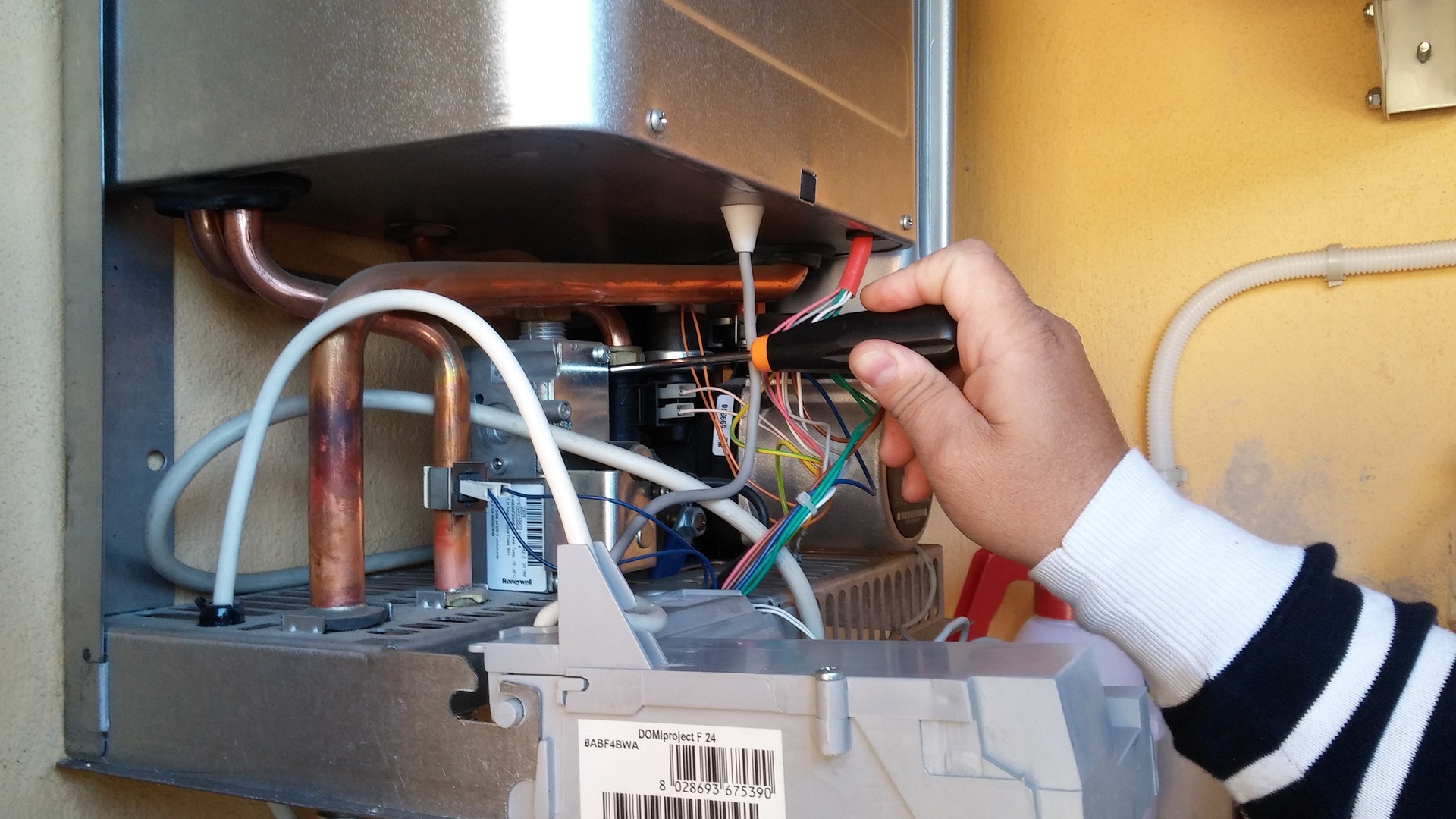

Boiler systems play a central role in home heating, and proper installation or timely repairs can help maintain consistent performance. This guide explores what homeowners should know about boiler installation, repair needs, and key considerations when planning system updates or maintenance.

Key Factors to Consider When Installing a New Boiler

Selecting the right boiler for your property involves several important considerations. First, you’ll need to determine the appropriate type of boiler—conventional, combination, or system—based on your home’s size, hot water demands, and existing infrastructure. Conventional boilers require separate hot water cylinders and cold water storage tanks, while combination boilers provide hot water on demand without additional storage. System boilers incorporate a hot water cylinder but don’t require a cold water tank.

Sizing is equally crucial, as an undersized boiler will struggle to meet your heating needs, while an oversized unit will operate inefficiently and increase energy costs. Professional installers typically calculate the required output based on property size, insulation levels, number of radiators, and hot water requirements. Most UK homes require boilers ranging from 24kW to 40kW, depending on these factors.

Energy efficiency ratings should also influence your decision, with modern A-rated condensing boilers offering efficiency levels of 90% or higher. These units can significantly reduce carbon emissions and energy bills compared to older models. Additionally, consider the boiler’s warranty period, which typically ranges from 2-10 years depending on the manufacturer, as this reflects the company’s confidence in their product’s reliability.

Common Issues That May Require Boiler Repair

Even well-maintained boilers can develop problems that necessitate professional repair. Low water pressure is among the most frequent issues, often resulting from leaks, bleeding radiators, or pressure relief valve problems. When your pressure gauge reads below 1 bar, it indicates insufficient water in the system to circulate heat effectively. This may require repressurizing the system or addressing underlying leaks.

Unusual noises—including kettling, banging, whistling, or gurgling sounds—typically signal limescale buildup, air in the system, or pump problems. These issues not only create disruptive noises but can lead to reduced efficiency and potential component damage if left unaddressed. A qualified heating engineer can diagnose the specific cause and recommend appropriate treatment.

Pilot light failures represent another common repair need, particularly in older boilers with standing pilot lights. When this component repeatedly extinguishes, it often indicates thermocouple issues, draft problems, or gas supply interruptions. Modern boilers with electronic ignition systems may display error codes when ignition fails, requiring technical diagnosis to resolve the underlying electrical or gas supply issues.

Frozen condensate pipes present a seasonal challenge during cold weather, causing boilers to shut down as a safety measure when condensation cannot properly drain. While this can sometimes be resolved by carefully thawing the external pipe, it’s important to identify why the freezing occurred to prevent recurrence in future cold snaps.

Benefits of Scheduling Routine Boiler Maintenance

Regular professional servicing offers numerous advantages beyond simply fulfilling warranty requirements. Annual maintenance allows technicians to identify and address minor issues before they develop into costly emergency repairs. This proactive approach can significantly extend your boiler’s operational lifespan, which typically ranges from 10-15 years with proper care.

Maintenance also preserves energy efficiency by ensuring all components operate optimally. A well-maintained boiler consumes less fuel to produce the same heating output, potentially reducing energy bills by 5-10% compared to neglected systems. This efficiency preservation is particularly valuable given rising energy costs.

Safety represents perhaps the most critical reason for regular maintenance. Professional inspections check for carbon monoxide risks, pressure issues, and electrical hazards that could endanger household occupants. Gas-safe registered engineers conduct comprehensive safety checks during servicing appointments, providing peace of mind regarding this essential home system.

Understanding Boiler Installation and Replacement Costs

The financial investment in boiler installation varies significantly based on several factors, including boiler type, capacity, brand, and installation complexity. Understanding these cost elements helps homeowners budget appropriately for this essential home improvement.

| Boiler Type | Average Supply Cost | Average Installation Cost | Total Cost Range |

|---|---|---|---|

| Combination | £600-£1,500 | £500-£1,000 | £1,100-£2,500 |

| System | £800-£2,000 | £600-£1,200 | £1,400-£3,200 |

| Conventional | £800-£2,200 | £700-£1,300 | £1,500-£3,500 |

| Premium Brand Models | £1,500-£3,000+ | £800-£1,500 | £2,300-£4,500+ |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Installation complexity significantly impacts overall costs, with straightforward replacements of the same boiler type costing considerably less than system conversions requiring new pipework or relocations. Additional factors affecting price include property accessibility, removal of old equipment, system power flushing requirements, and installation of supplementary components like water filters or thermostatic controls.

Most qualified installation companies offer warranties on both parts and labor, typically ranging from 1-10 years depending on the manufacturer and installation provider. While selecting the lowest-cost option may seem appealing, prioritizing quality installation from Gas Safe registered engineers with positive reviews helps ensure safety, efficiency, and long-term reliability.

Selecting a Qualified Boiler Engineer

Finding the right professional for installation or repairs significantly impacts your boiler’s performance and safety. All gas boiler work in the UK legally requires a Gas Safe registered engineer, whose credentials can be verified through the official Gas Safe Register. This certification ensures the engineer has received appropriate training to work safely with gas appliances.

Experience with your specific boiler brand offers additional advantages, as manufacturer training provides engineers with specialized knowledge of particular systems. Many reputable heating companies employ engineers certified by major manufacturers like Worcester Bosch, Vaillant, or Baxi, ensuring they understand the intricacies of these systems.

When evaluating potential service providers, review customer feedback through established platforms like Checkatrade, Trustpilot, or Google Reviews. Focus on comments specifically addressing boiler work rather than general plumbing services. Additionally, request detailed written quotes from multiple providers before committing, ensuring all aspects of the installation or repair are clearly specified to avoid unexpected costs.

By taking time to understand these key aspects of boiler installation, repair, and maintenance, homeowners can make informed decisions that maximize system performance while minimizing long-term costs and inconvenience.