Insulating Cavity Walls: Common Materials and Installation Insights

Cavity wall insulation can help reduce heat loss and improve indoor comfort when installed correctly. This guide explores the most commonly used materials, how the installation process typically works, and what property owners should consider before getting started.

Materials Commonly Used for Cavity Wall Insulation

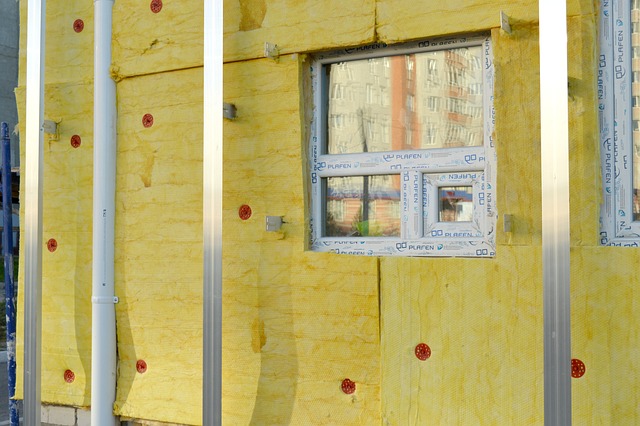

Several insulation materials are specifically designed for cavity wall applications, each with distinct properties and benefits. Mineral wool (either rock or glass wool) remains one of the most prevalent options, consisting of fibers formed into batts or loose-fill materials. This material offers excellent thermal and acoustic properties while remaining fire-resistant and relatively cost-effective. Polystyrene beads represent another common solution, particularly in hard-to-reach areas. These small beads, often treated with a bonding agent, provide reliable insulation while flowing easily into irregular spaces.

Polyurethane foam has gained popularity for cavity wall applications due to its superior thermal performance. When sprayed into the cavity, it expands to fill the entire space, creating an effective thermal barrier and adding structural strength to the wall. Urea formaldehyde foam, while less common today due to environmental concerns, still features in some installations, particularly in older retrofits where its flow characteristics work well in irregular cavities.

Cellulose insulation, made from recycled newspaper treated with fire retardants, offers an environmentally friendly alternative. Though more frequently used in loft insulation, specialized forms can be suitable for cavity wall applications, particularly in properties where natural materials are preferred.

How the Installation Process is Carried Out

The standard installation process for cavity wall insulation follows a systematic approach designed to ensure complete coverage without compromising the wall structure. Initially, a professional installer conducts a thorough survey of the property to confirm suitability, checking wall condition, cavity width, and potential obstructions. This assessment determines whether cavity wall insulation is appropriate and which material would work best.

For the actual installation, technicians drill small holes (approximately 22mm in diameter) in the external wall at strategic points, typically at intervals of 1-1.5 meters horizontally and vertically. These holes provide access points for inserting the insulation material. Using specialized equipment, the installer then injects or blows the chosen insulation material into the cavity until it reaches the appropriate density throughout the entire wall space.

Modern installation equipment includes monitoring systems that help ensure uniform distribution throughout the cavity. Once the cavity is fully filled, technicians seal the drill holes with mortar matched to the original wall color, making the intervention virtually invisible once completed. A typical installation for an average UK semi-detached house takes between 2-3 hours, with minimal disruption to the household.

Factors to Consider Before Insulating Cavity Walls

Several important considerations should inform any decision to install cavity wall insulation. First, not all properties are suitable candidates—homes in areas with high wind-driven rain exposure may face increased damp risks after insulation if the external walls aren’t sufficiently weather-resistant. Similarly, properties with pre-existing damp issues should address these problems before installing insulation.

The width of the cavity itself represents another crucial factor. Standard cavities measuring at least 50mm wide typically accommodate most insulation types, but narrower spaces may require specialized materials. Properties with irregular cavities or those containing significant rubble or debris may need cavity clearing before installation can proceed safely.

Building regulations and permissions also warrant attention. While cavity wall insulation generally doesn’t require planning permission, the work must comply with current building regulations. In conservation areas or listed buildings, special considerations or restrictions may apply, potentially requiring alternative approaches to improving thermal efficiency.

The property’s age and construction type significantly impact suitability. Homes built before 1920 typically feature solid walls rather than cavity construction, making them unsuitable for this specific intervention. Conversely, properties built after 1990 often already have insulation installed during construction, making additional treatment unnecessary.

Cost Considerations and Financial Benefits

The investment required for cavity wall insulation varies depending on property size, wall condition, and the specific material chosen. For a typical UK three-bedroom semi-detached house, costs generally range between £450 and £700 for professional installation. Larger detached properties might require investments of £700-£900, while smaller terraced houses typically cost £330-£500 to insulate.

| Property Type | Average Cost Range | Potential Annual Savings* | Typical Payback Period |

|---|---|---|---|

| Mid-terrace | £330-£500 | £120-£150 | 2-4 years |

| Semi-detached | £450-£700 | £160-£200 | 2.5-4.5 years |

| Detached | £700-£900 | £230-£270 | 3-4 years |

| Bungalow | £400-£600 | £140-£180 | 2.5-4 years |

*Savings based on Energy Saving Trust estimates for a gas-heated home

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Several financial incentives may offset these costs. The Energy Company Obligation (ECO) scheme provides support for qualifying households, particularly those with low incomes or receiving specific benefits. Additionally, the improved energy efficiency typically results in noticeable heating bill reductions, with most homeowners recouping their investment within 2-5 years through lower energy costs.

Professional Assessment and Quality Assurance

Professional assessment constitutes a critical component of successful cavity wall insulation. Reputable installers should be registered with the National Insulation Association (NIA) or the Cavity Insulation Guarantee Agency (CIGA), which provides 25-year guarantees for properly installed systems. These organizations maintain standards and provide consumer protection should issues arise post-installation.

During assessment, qualified surveyors will check for signs that might indicate potential problems, such as existing penetrating damp, cracked pointing, or damaged brickwork. They should also verify that the cavity is clean and of sufficient width for the proposed insulation material. A comprehensive survey includes a borescope inspection to examine the actual cavity condition, ensuring there are no obstructions that might lead to incomplete filling and subsequent cold spots.

Conclusion

Cavity wall insulation offers significant potential for improving home energy efficiency when appropriate materials are correctly installed in suitable properties. The range of materials available—from mineral wool to polyurethane foam—provides options for different building types and requirements. Proper professional assessment, quality installation, and consideration of all relevant factors are essential for achieving the desired thermal improvements without creating unintended consequences. For most suitable properties, the combination of energy savings, increased comfort, and reduced carbon footprint makes cavity wall insulation a worthwhile investment in home improvement.